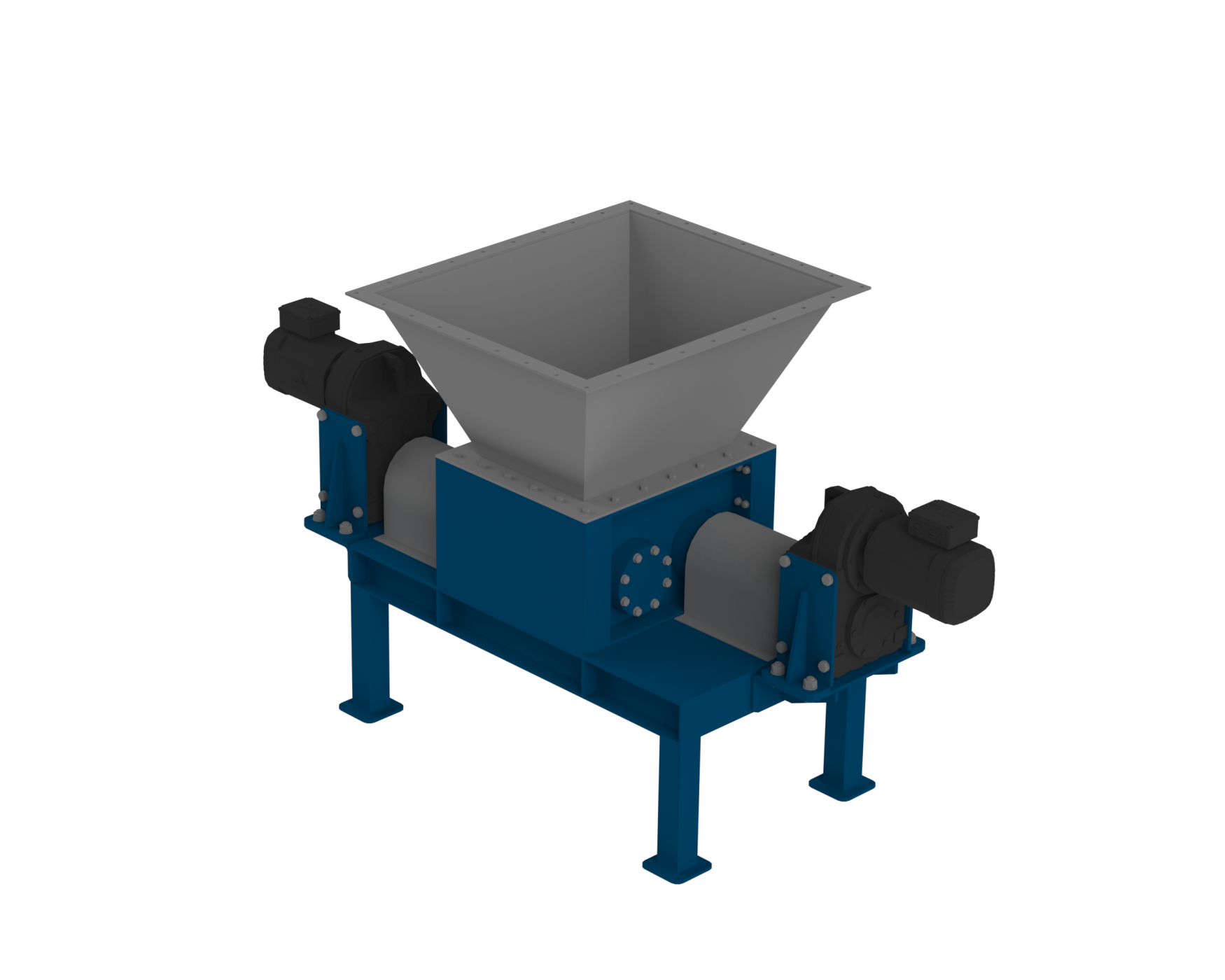

Animal By-Products Crusher

Advantages:

Animal Rendering Crusher

The crusher is designed to crush the cooked animal by-products. Raw material after cooking is fragile and easy to crush. The final product coming out of the crusher is not larger than about 20-30 mm. The machine consists of a steel frame, processing chamber, gear motor, two robust and durable shafts with knives. The gearbox is mounted by a steel plate. The motor is equipped in full copper core, which reduces energy consumption, is durable, energy-saving, and prolongs its service life.

General application of shredders

Animal shredders are widely used in the rendering industry, food industry, and feed industry. In general, they are used for various internal organs and bones from slaughterhouses. The rendering requires consistent material for processing. Properties and particle size of this product impact directly on heat transfer efficiency during drying or cooking. The main aim of the crusher is to reduce the size of the material transported by a screw conveyor or lamella pump. Sometimes pre-breaker is necessary at the beginning of the process, and sometimes crusher is necessary to crush cooked animal bone and meat. Shredders are also used for leftovers from animals like beef, cattle, and poultry.

Main features

- Power-saving drive unit

- A low-speed shaft can handle metals in raw materials

- Material inlet and outlet are equipped with removable butt flanges

- Wear parts can be replaced easy and fast

- The motor is stopped immediately when large matter enters the crusher

- Equipped with electronic speed monitoring

- Spindles are equipped with heavy-duty bearings, which can resist large axial and radial impact

- Standard parts are utilized for driving from the motor to the shaft

- High hardness heat-treated blades - longer life and more powerful cutting

Knives made of wear-resistant steel

Knives made of wear-resistant steel

Download technical data sheet

Download technical data sheet