Storage tanks and raw material bins

Fish and meat rendering plants, which are processing animal by-product materials, need different storage equipment. That plants cooperate with animal slaughterhouses. Demand for industrial storage machines is high. Materials like blood, feathers, fat, and meat require storage solutions for liquid and solid material. TG-Machines can deliver two types of storage equipment. Raw material bins and steel tanks.

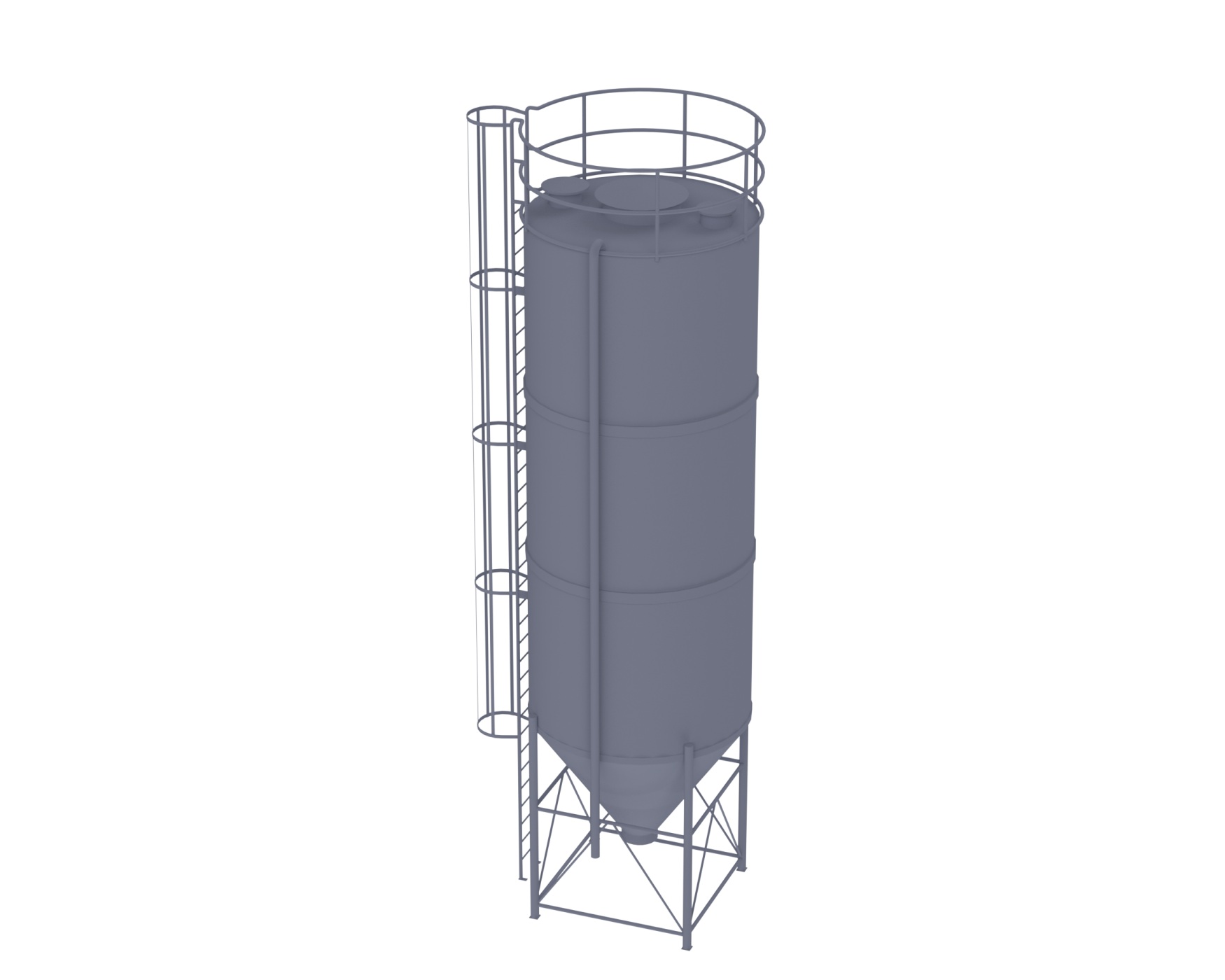

Steel tanks

Steel storage tanks are designed to hold liquids, compressed gases, or different mediums hot and cold for the short or long term. A storage tank can be designed by our engineers according to defined specifications as a pressure vessel if it is necessary. Sometimes special solutions have to be applied like double-wall design when high pressure is acting or heating coil inside the steel storage tank. Our tanks can be fabricated with mixing agitators, access platforms, ladders, handrails, and insulation. Tanks are available in stainless steel and carbon steel. When it is necessary, special acid-resistant tank material can be utilized. Steel storage tanks can be applied to the storage of blood, oil, stick water, condensate, water, fish meal, water, CIP liquid, and fat.

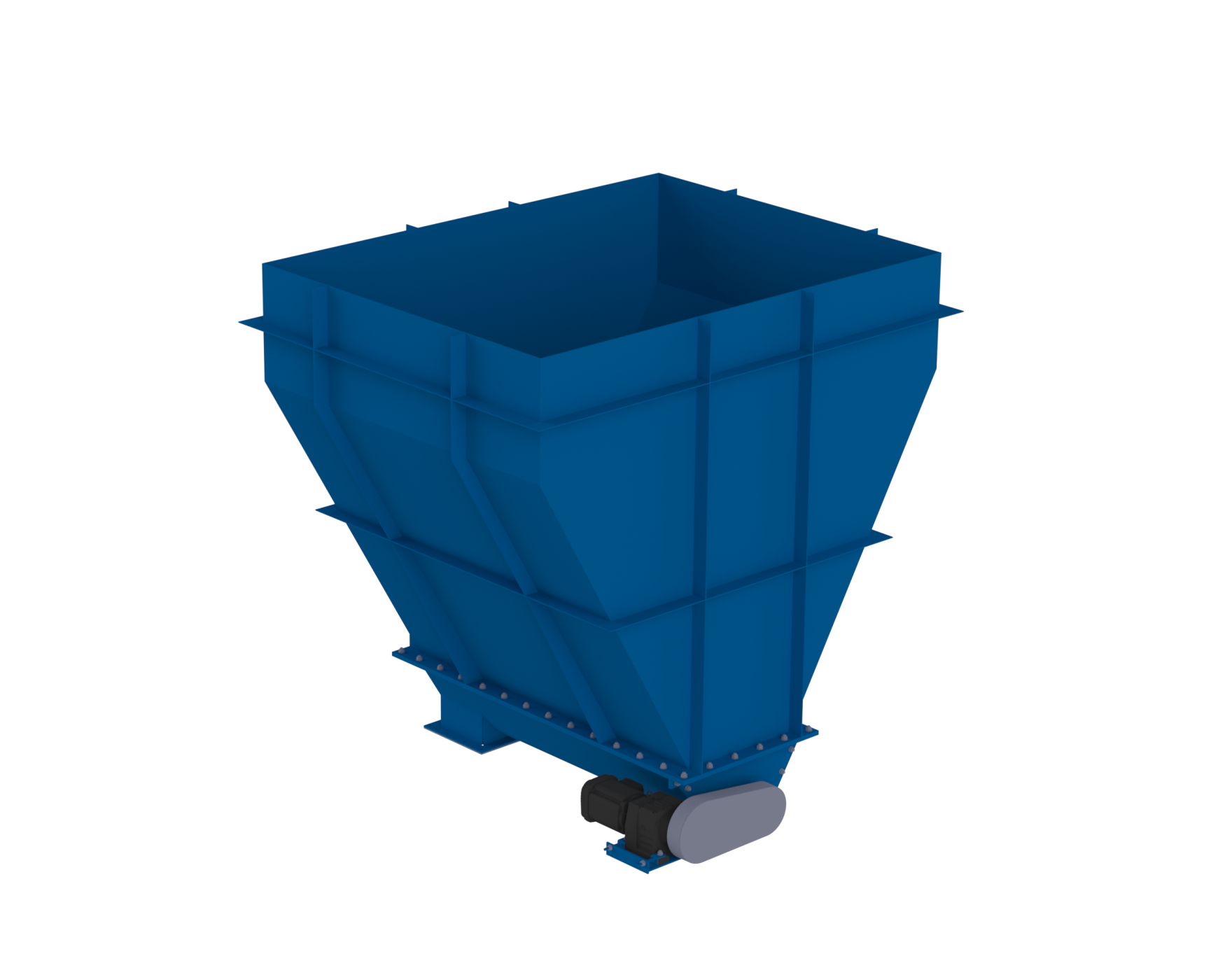

Raw material bin

The raw material bin is the first element of the rendering production line for the storage of feathers, meat, fish offal, fatty tissue, pork, sheep, beef, and poultry. It can be installed above the ground and sometimes for customer requests it is possible to make a bin for underground storage. The raw material is transported with a truck and a special design of the bin allows direct unloading of the material to the bin. Each steel hopper is custom-made according to customer requirements. A load cell system for monitoring the weight of the raw material and automatic hydraulic lids can be installed. We offer versions made of stainless steel or carbon steel.