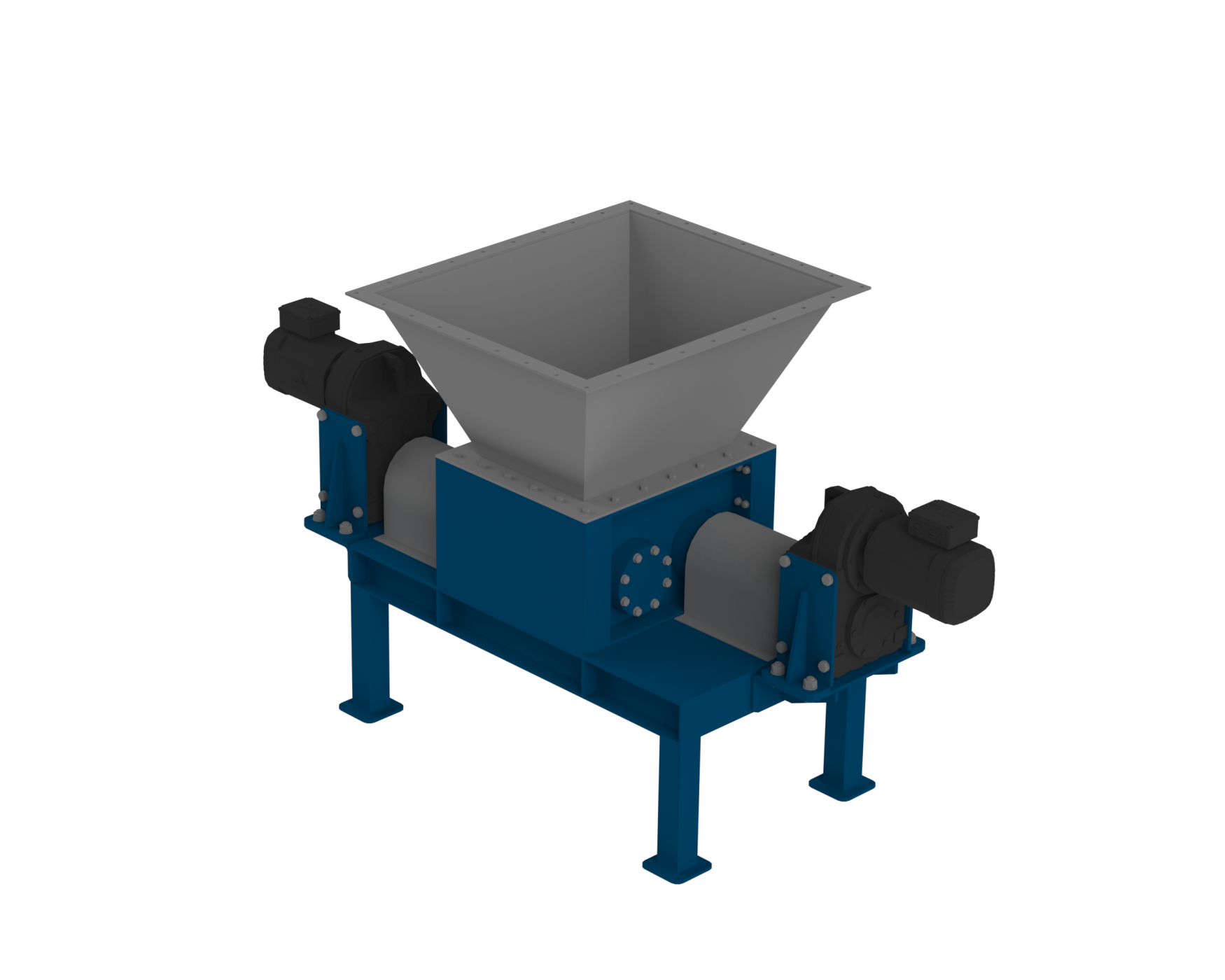

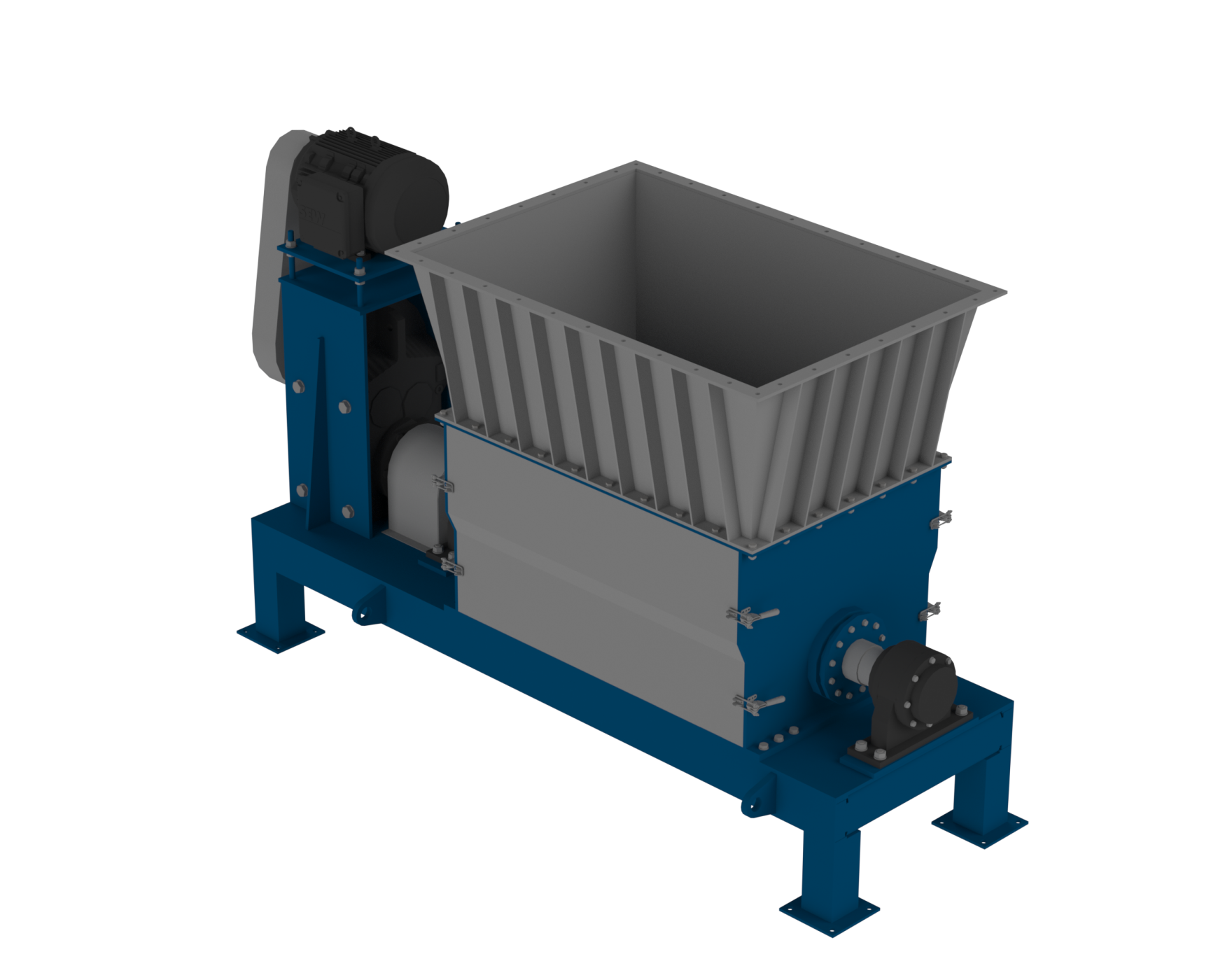

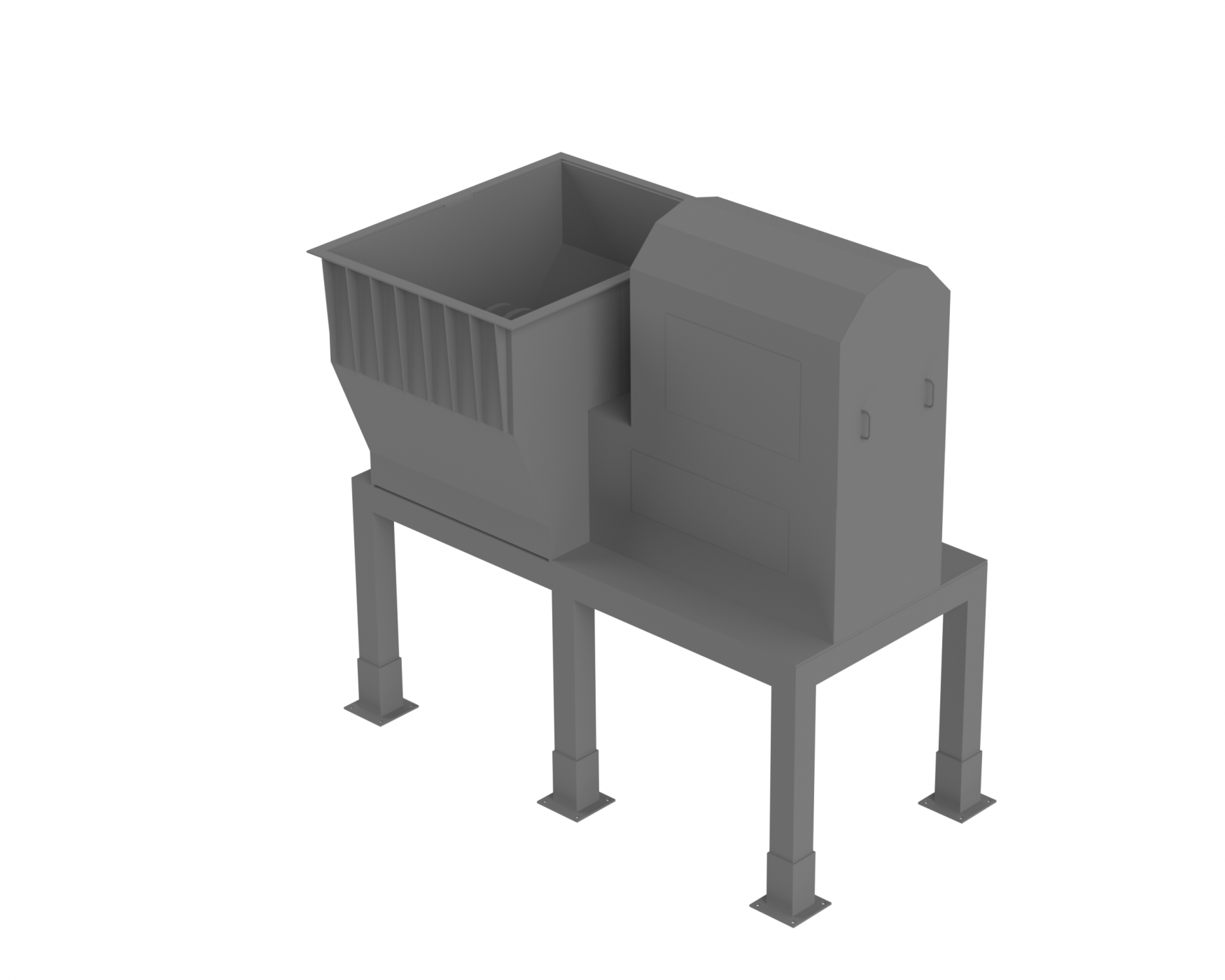

Fresh and frozen meat grinders (crushers)

Industrial crushers and meat grinding machines are used mainly in meat and fish rendering plants for both dry and wet temperatures applications. Crushers are utilized for the size reduction of the raw material. The crushed material is conveyed by a screw conveyor or lamella pump to the cooking or drying equipment.

Crushers are equipped with heavy-duty shafts, which are rotated by energy-efficient motors. The velocity of the crusher rotor can be adjusted according to the production demand. The operation cost of an industrial crusher is low. Machine design is performed to enable the easy and quick replacement of spare parts, which makes the crusher a more efficient machine for the meat and fish rendering industry.

Commercial meat grinder application for rendering materials from the slaughterhouse

Industrial crushers are used for crushing fatty tissue, pork, sheep, beef, offal, and bones from meat and poultry slaughterhouses. Complete carcasses of animals that die can be processed. In meat rendering plants, sometimes materials such as slaughterhouse hair, blood, and feathers can be crushed. Animal by-products from pork, poultry, beef, and sheep are the most popular sources of raw material in rendering operations. Frozen meat crushers can deal with frozen blocks of different raw materials like frozen fish, frozen animal by-products, and frozen poultry by-products. The grinder is made from stainless steel. It ensures a very good processing capacity of meat per minute.

Meat grinder manufacturer

TG-Machines is manufacturing different types of industrial shredders with high capacities. In our offer, we have animal by-products crusher, animal rendering pre-breaker, frozen meat grinder, and crusher for meat, fish and feathers. High-performance shredders can handle small metal elements in raw materials. Each machine is equipped with electronic sensors responsible for stopping the crusher when a large material enters the machine. The robust crusher shaft is supported by heavy-duty bearings from both sides. The machine can withstand strong radial and axial impacts. The crusher is equipped with a standard energy-efficient gearbox and motor. It is possible to make custom-made material inlet. The outlet is equipped with removable butt flanges.