What is condensate?

Condensate is created when steam passes from vapor to liquid state. Condensate is formed during heating, and when steam transfers some of its thermal energy, known as latent heat, to the equipment or product.

What is flash steam?

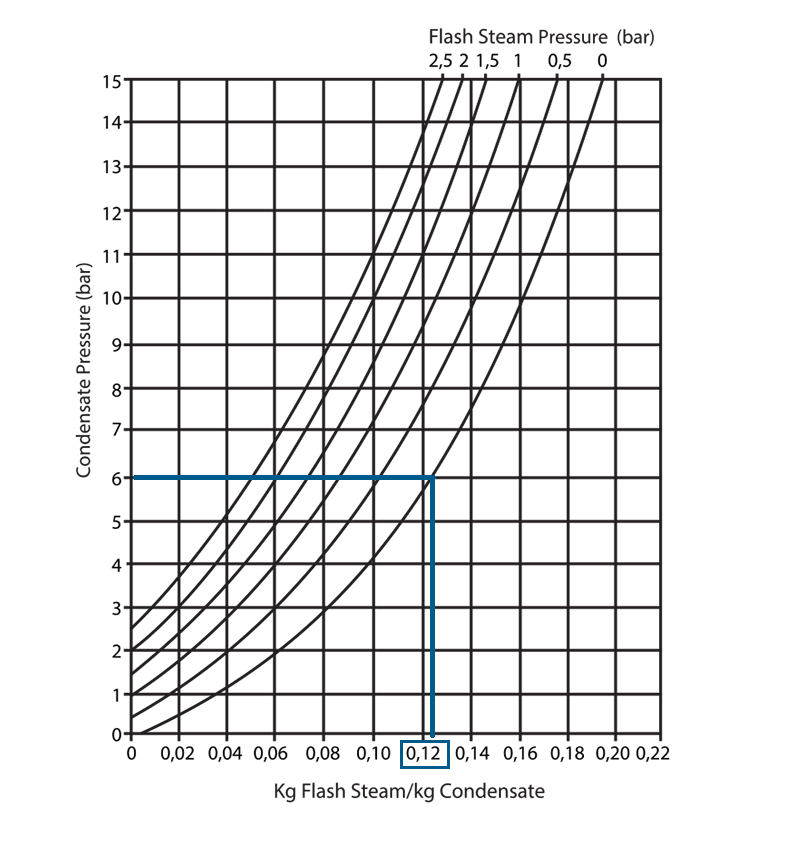

Flash steam occurs when high temperature and high-pressure condensate is exposed to a large pressure drop. For instance, when condensate is exiting a steam trap.

If one ton of steam is supplied for the heating process to the equipment, the same amount of the condensate must be unloaded from the machine. Condensate recovery relies on reusing sensible heat and water contained in the condensate. Flash steam utilization can lead to significant savings of energy, chemical treatment, and makeup water. Steam and boiler efficiency is increased widely. The condensate return system is utilizing condensate as a valuable resource of heat energy. Condensate saving is used in steam systems.

Return condensate application

- Hot water, for equipment cleaning and cleaning purposes

- In the form of steam, by reusing of flash stem

- As pre-heating for any suitable heating system

- Heating of feed water

- Sending hot condensate back to the boiler

- Condensate recovery as a part of the water treatment system

Benefits of condensate recovery system

The reuse of hot condensate can lead to significant savings in energy and water resources, as well as improved operating conditions. Reducing water supply and treatment costs. Condensate strainers are responsible for removing any impurities picked up during condensate transport.

Energy savings and fuel costs

The condensate contains a large amount of sensible heat, which may be about from 10% to 30% of the thermal energy contained in the vapor. Boiler output efficiency is maximized during feeding the boiler with high-temperature condensate. Less heat energy is required to turn water into saturated steam. Boiler fuel can be reduced even by 20% when condensate is recovered and reused. Our company is using spirax sarco equipment. For condensate recovery systems, specially designed return piping is installed with control valves, steam traps, and filters.