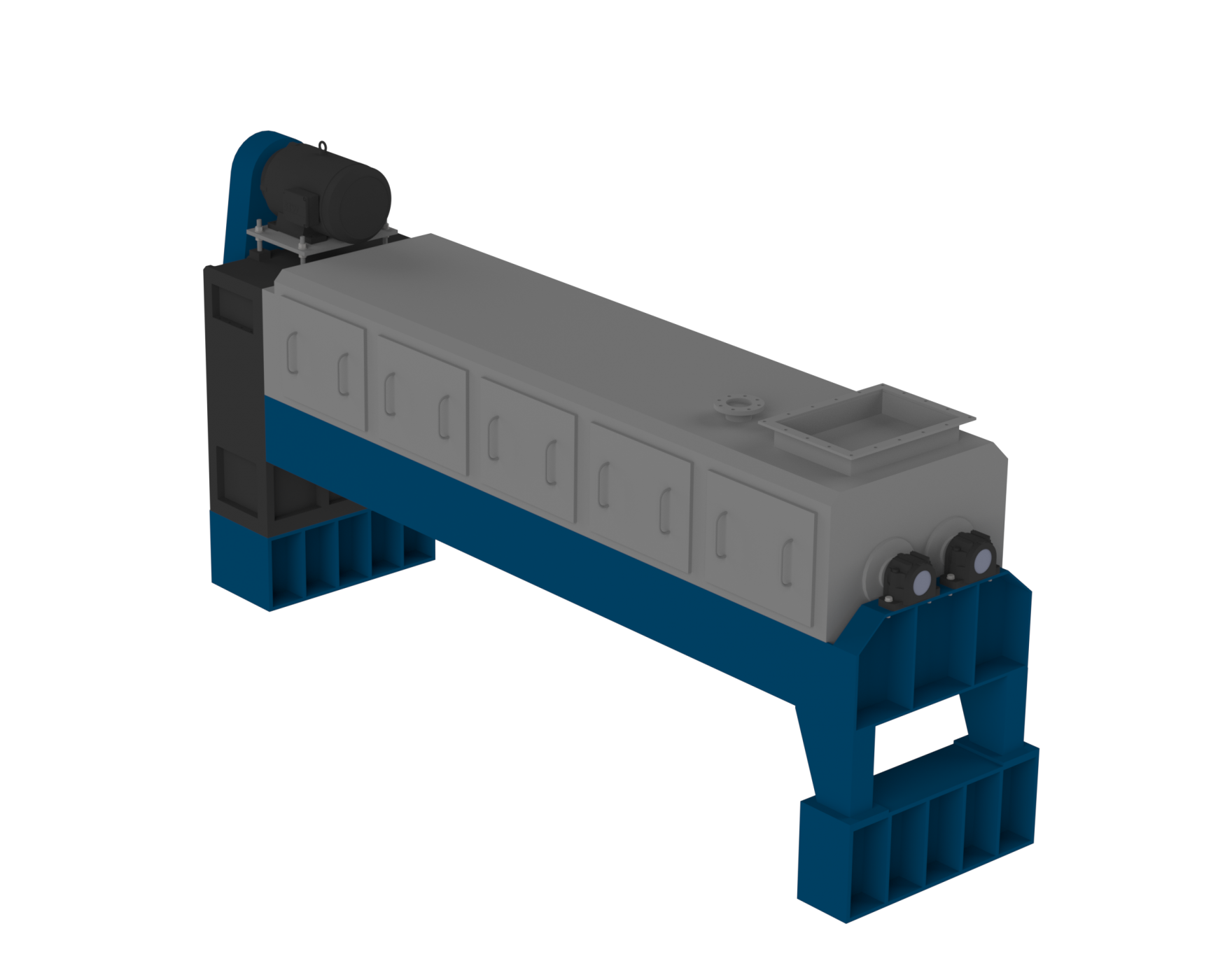

Screw press for mechanical dewatering

A screw press is a machine for mechanical dewatering, which separates liquids from solids. The raw material is fed directly into the horizontal screw press inlet. It has a conical shaft with variable pitch welded flights. Existing different squeezing ratios guarantee very good control of the moisture and fat content of the press-cake. Pressing take place in a cylindrical press chamber between the upper and lower screen cage. The cylindrical wall is built from thick strainer plates, which are made from stainless or carbon steel. The dewatering screw press consists of a cone shaft which ensures even compression of the material. The most popular and the most reliable type of screw press is a twin screw press. Modern and cost-effective machine for the mechanical dewatering of different raw materials.

Twin screw press

The twin screw press is used for separating liquid from cooked fish or meat. It is a perfect, alternative for the decanter and the lifetime of screw presses is much longer. There is no need for replacing wear out parts so often, like in the centrifuge decanter. The twin screw press is rotating slower at approximately 5rpm and the decanter at 3600rpm. A horizontal twin screw press can be applied for land base fish meal and rendering plants, and also compact fish meal plants aboard trawlers. It is driven by an energy-efficient gearbox and motor, with a frequency inverter that can be installed for a wide range of speeds, applied to various species of raw material. A hydraulic oil cooling system is mounted for gear lubrication. In the twin screw press, dewatered press-cake is conveyed and pushed out through an outlet placed below the machine.

The twin screw press design ensures the dewatering performance of different volumes of the raw material, which is pumped directly into the press inlet. Spindles are rotating in opposite directions, preventing the mass from rotating. Easy to operate, installation and maintenance, low energy consumption, and low maintenance costs.

Twin screw presses are pressing the material with extremely high pressures and enormous torque. Hollow interlocked cylinders and robust screws are perfect for extracting the liquid from cooked raw material. TG-Machines can deliver spare parts and screw presses with a wide range of capacity according to the customer's requirements. Dewatering systems with the twin-screw press are working worldwide in food processing factories.