How does a lamella pump work - working principle

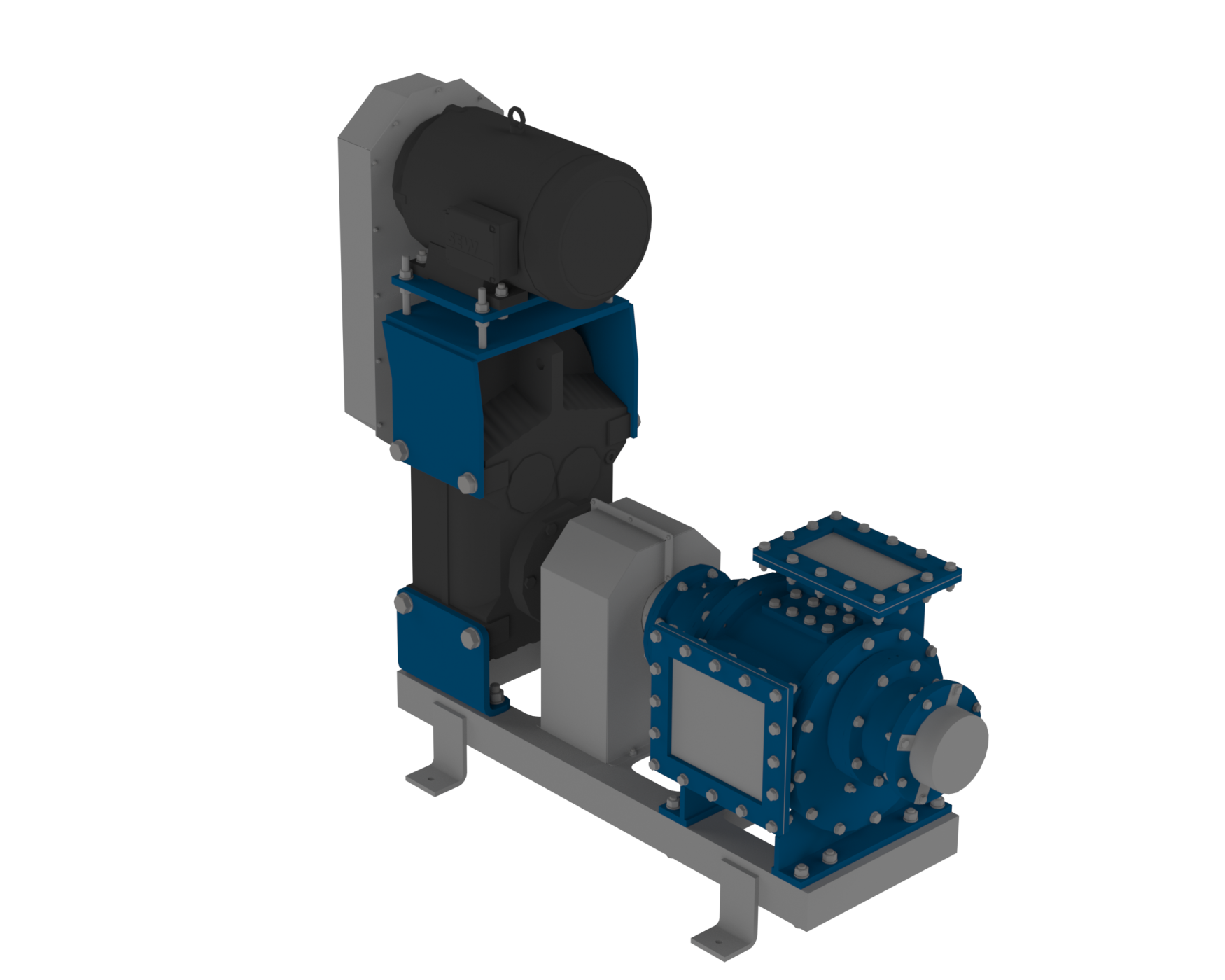

Lamella pump is used for the toughest applications. Reliable and high-capacity machine, well known for its extensive durability. It consists of a housing in cast iron or stainless steel, two sets of bearing supporting a central shaft, and sliding vane blades. The pump unit is placed on a small steel platform. Specially designed robust coupling is connecting the lamella pump with the drive unit, which consists of an energy-efficient motor, gearbox, and belt transmission. The machine is equipped with inlet and outlet connections.

Rendering pump for toughest tasks

TG Machines lamella pumps are intended to pump raw material with high viscosity, such as material from meat rendering, processing plants, and products of animal origin. Durable construction allows pumping large, hard particles such as crushed bones, tissues, and pre-broken animal by-products with a small liquid flow. The pump is suitable for fish, bone, and offal transfer over long distances. In general, it can be used for non-homogeneous products. Its proven suitability for many applications is verified when the device is installed in the industry all over the world. It can be used in wet and dry temperature rendering. Lamella pump works perfectly as a closed transport system for loading cookers and other processing equipment, reducing unpleasant odor.

The machine is available in several versions to suit individual requirements, thus enabling a perfect fit for your specific production needs. Lamella pump is replacing conveying systems such as screw conveyors, conveyor belts, and cavity pumps. It has a high operational capacity simultaneously maintaining low energy consumption and low maintenance costs, All wear-out parts are replaceable and can be changed fast and easily. Factors like quality, functionality, and many years of development made us a leading manufacturer of the lamella pump.

Quality of lamella pump

- The robust design of each pump is made with high-quality and durability

- TG-Machines work closely with our customers, as we are ready and open to new innovative solutions

- Spare parts are available worldwide, we offer full overhaul of the delivered pumps

- The pump can be delivered with hardened steel elements

- Manufactured in high-quality wear-resistant steel parts

If you require more information about the available solutions, please contact us via the contact form on the last tab or by e-mail: info@tg-machines.com or call us.

For more technical information, please see our technical data sheet.

High efficiency, positive displacement pump

High efficiency, positive displacement pump

Download technical data sheet

Download technical data sheet