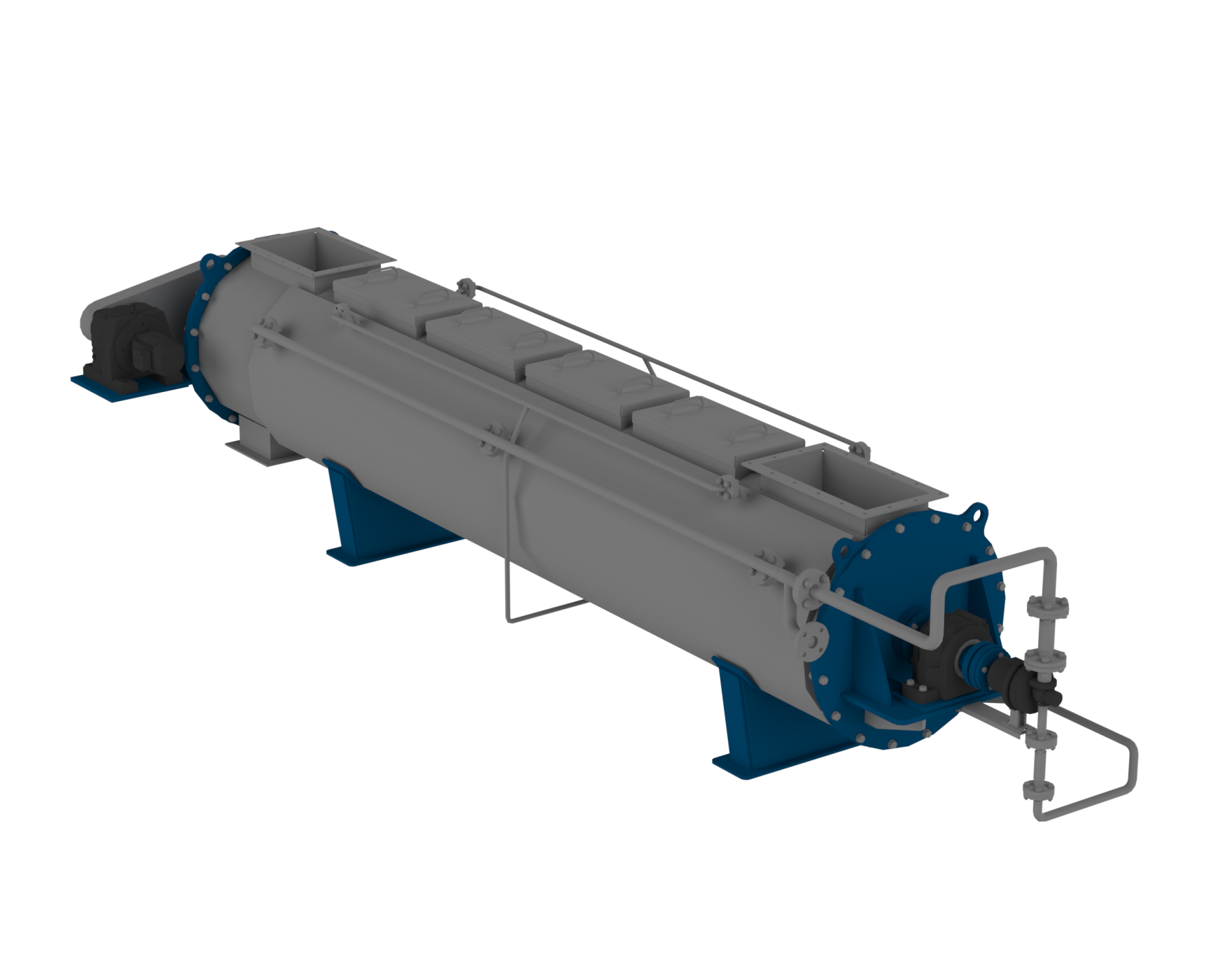

Rendering Continuous Cooker

Advantages:

How does a rendering continuous cooker work - working principle

Cooking is performed by saturated steam. The machine consists of a screw rotor, stator housing, steam jacket, gearbox, efficient electric motor, and belt transmission. Screw flights are welded perpendicularly to the rotor. Stator housing can be equipped additionally with insulation and stainless steel cladding. Uniform distribution of the steam for the outer shell is achieved by equally divided stator sections. Indirectly steam-heated product is continuously mixed and moved along the machine. Rendering continuous cooker can be equipped with an automatic temperature control system, level control sensors, and discharge control system. The steam jacket can be equipped with air intake nozzles and with direct steam nozzles for blowing pure steam. The covers are mounted on the top of the machines for cleaning and easy interior inspection.

Characteristics of a rendering cooker

The rendering machine is mainly used for all types of fish meal plants and for poultry rendering plants. It is operating at a low rotation speed in order to preserve the raw material structure and proteins during processing. Gentle mixing ensures a better separation of dry solids, water, and oil. It is a robust and energy-efficient machine for a small and big volume of raw material, with a capacity from 2 to 40 metric tons per hour. The heating process of meat rendering takes place at approximately 95ºC between the flights and by the steam jacket. For preheating and cooking flexibility, frequency inverter and variable steam pressure controls are mounted. According to the different properties and requirements, of processed material, machines can be made of carbon or stainless steel. Cookers are subject to detailed quality control. Rendering continuous cooker produced by our company requires minimal operation input because automatic controls system is responsible for controlling the cooking time. TG-Machines is supporting continuous and batch systems.

If you need more information about the available solutions and equipment, please contact us via the contact form on the last tab or by e-mail: info@tg-machines.com or call us.

For more technical information, please download our technical data sheet

Energy-efficient

Energy-efficient

Download technical data sheet

Download technical data sheet