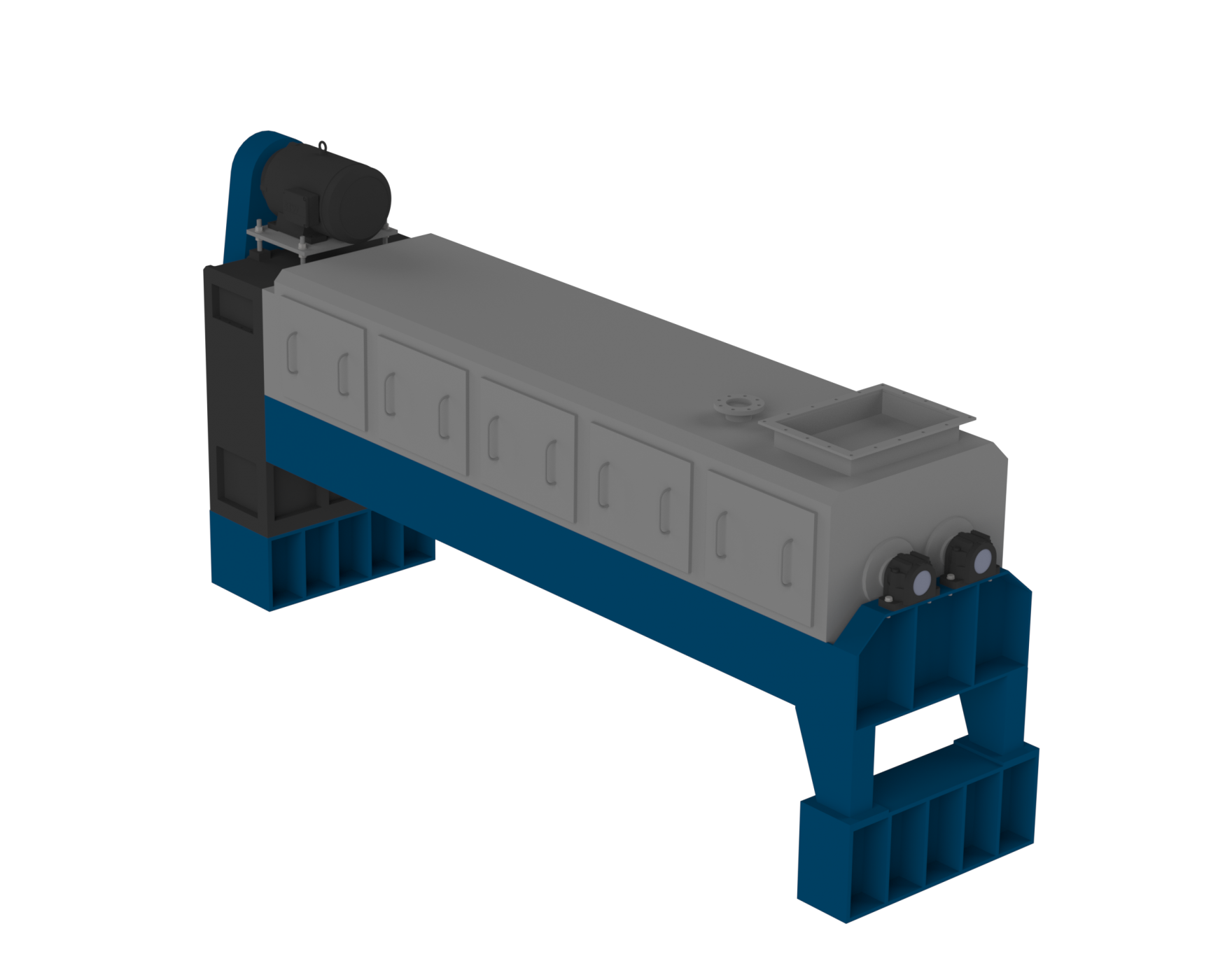

Twin Screw Press

Advantages:

How does a twin screw press work - working principle

A twin screw extruder consists of two cylindrical counter-rotating screws with welded flights. The robust gearbox is mounted with an energy-efficient motor. The spindles are covered by a strainer shell, which is supported by specially designed bridges. Upper and lower cages are fixed together by durable clamps. The inlet is placed on the opposite side of the high torque gearbox. At the top of the cover, there is an air intake flange connected to the odor management system. On the market, two types of presses exist, cylindrical and bio-conical options. Welded on spindle flights can be cylindrical or conical. Counter-rotating spindles are designed with a progressively reduced pitch. Material entering the inlet is subjected to gradually increased pressure. The press-cake is pushed out through the outlet and subjected to further treatment.

Characteristics of a double spindle extruder

Twin screw press is mostly used in a low-temperature wet rendering, and it is perfect for extracting liquids from previously cooked meat or fish. Provide high-capacity continuous mechanical separation of water. It is designed especially for rendering plants to maximize the dewatering and oil pressing. The screw's velocity can be adjusted by the frequency inverter.

The twin screw press is a robust slow-rotating alternative for decanter centrifuges, which runs at a high speed of 3600 rpm. Spindles are rotating in opposite directions to squeeze and press the material. The slow velocity of the screws provides high solid content in the press cake. As a result, in the subsequent drying stage, energy savings will appear and less moisture will be in the pressed material. To suit different raw material types and capacities, varying compression ratios can be used. To ensure the continuity of the process, in-feed screw conveyors and chutes can be mounted, which are controlling the feeding level automatically. Machines are energy efficient, easy to operate and maintain. It can be built from stainless or carbon steel. We offer a wide range of long-life press sizes.

If you require more information about the available solutions, please contact us via the contact form on the last tab or by e-mail: info@tg-machines.com or call us.

For more technical information, please download our technical data sheet.

Energy efficiency

Energy efficiency

Download technical data sheet

Download technical data sheet