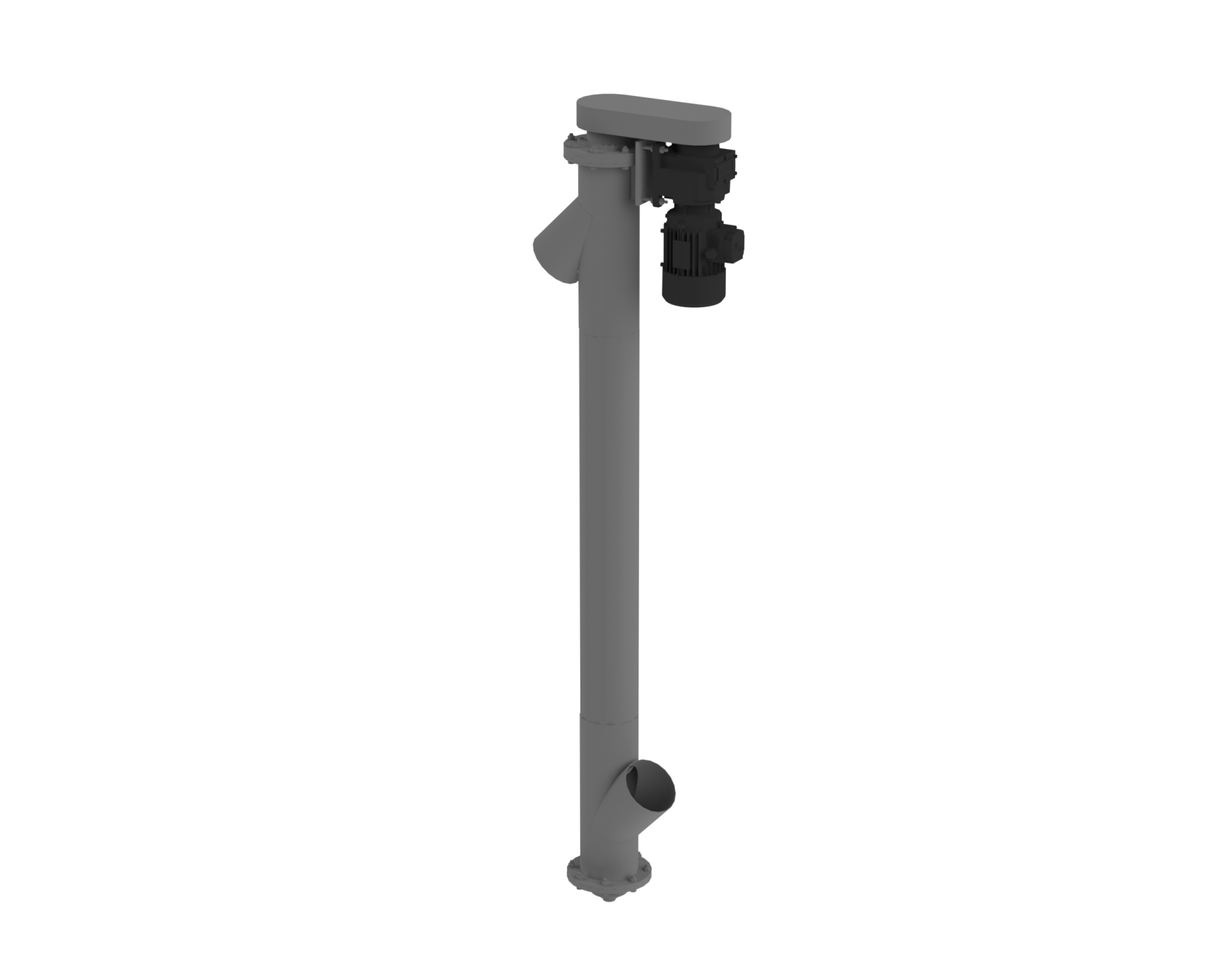

Vertical Screw Conveyor

Advantages:

What is a vertical screw conveyor?

A vertical screw conveyor is an efficient machine for elevating a variety of bulk materials, from steep slopes, to completely vertical ones. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and reliable part of any bulk material handling process. It is made in the shape of a pipe. It consists of two bearings seats, flights, shaft, bearing housing, and driven equipment. Shafts and screw flights are welded to the center tube. Rotations are initiated by an energy-efficient motor and a gearbox. The material is transported along the auger conveyor from the inlet to the outlet. In general, all screw conveyors look similar, but it differs due to the properties of the processing material, which can be fatty, dry, cold, hot, and wet. Design is made in order to achieve the best possible performance of the machine. The conveyor can be made according to the customer's requirements. Different options are available: variable pitch of the flight, extra outlet, extra inlet, etc.

What are screw conveyors used for?

Screw conveyors are used to transporting bulk materials from almost any position (horizontal, vertically, or at an angle) and are one of the reliable methods of transport. The screw conveyor consists of a tube with a welded steel strip formed into a continuous spiral. The spiral is called flight.

What are the types of screw conveyors?

Division based on the flow path: horizontal, inclined, and vertical screw conveyors. Other types of augers are shaftless augers and live bottom screw conveyors. Augers can be made of stainless steel or carbon steel.

What are the screw conveyor components?

- Screw shaft with welded flights

- Trough

- Bearings with housings

- Coupling

- Internal collar

- Gearbox and motor

- End plates

- Cover with clamps

- Legs or frame

- Inlet and outlet

Features of vertical auger conveyor

- Convey efficiently a wide variety of materials

- It occupies a very small footprint

- Only a few moving parts

- Reliability and durability

- Stainless steel and carbon steel materials

- Application for chemical, grain, food, mining, pulp & paper, rendering industry

- Dust and vapor tight designs are available

Energy-efficient drive unit

Energy-efficient drive unit

Download technical data sheet

Download technical data sheet