Waste Heat Evaporator

Advantages:

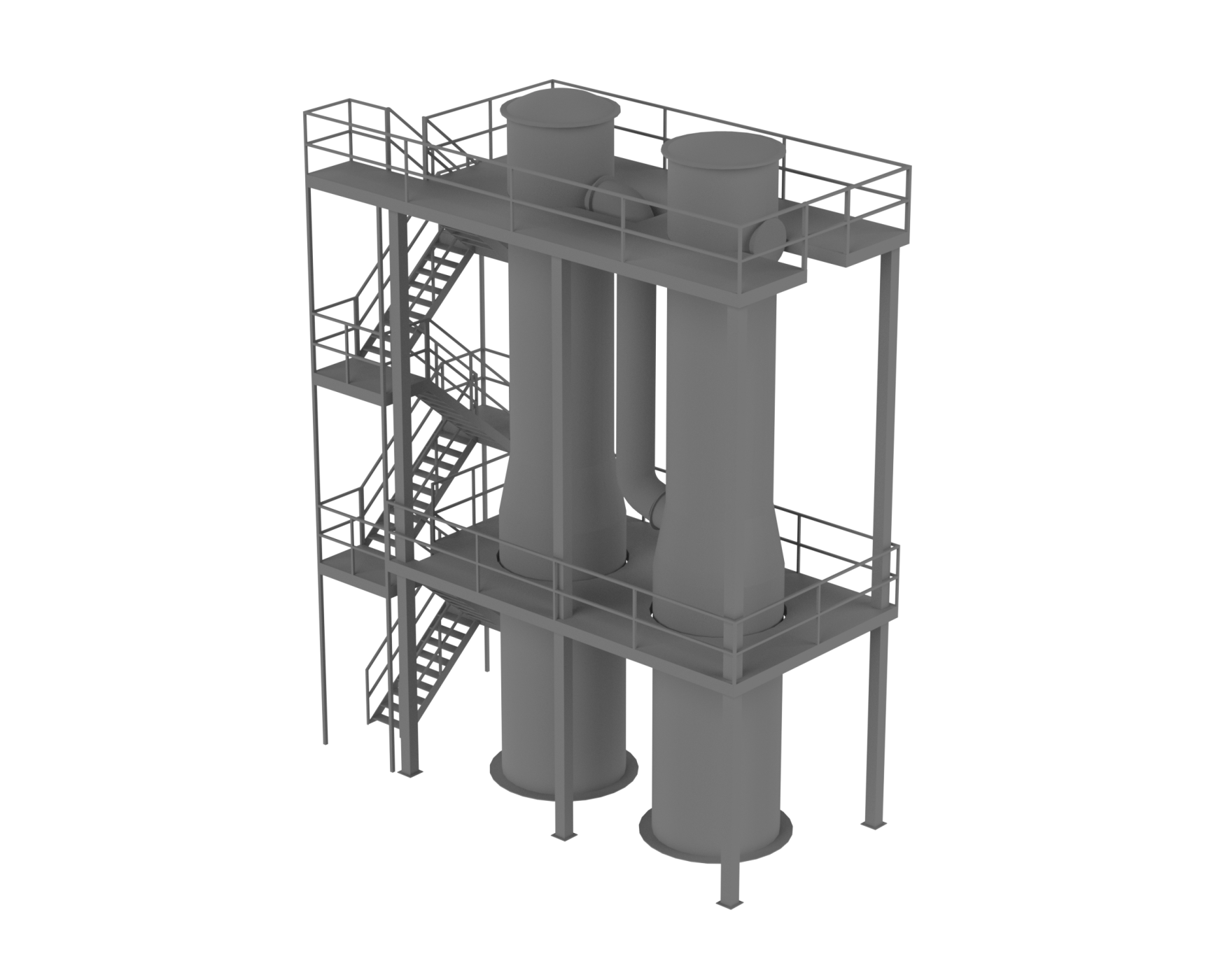

Falling film evaporator

The most important and only goal of a waste heat evaporator is to save energy and reduce steam consumption. TG-Machines can offer different configurations of the waste heat falling film evaporators. Single, Double, and Triple Stage Effects are available.

Waste heat recovery system for fish meal plants

The industrial evaporator allows steam consumption to be reduced by approximately 50%, it is especially significant when boiler fuel is expensive. The evaporator is used in fish meal plants where the cooker, press are working and the stick water, fish oil are separated. For the final decision on how many stages will be used in the process, the calculation has to be taken into account. For instance, for tuna waste where the level of the stick water is low, one stage will be enough. While for sardines where the level is higher, two stages of falling film thermal exchangers are required.

In contrast, a rotary disc dryer is a fish meal dryer for solid particles. The evaporator is a stick water dryer that comes from a decanter and a separator. The heat source for the evaporation process is condensed water vapor from the disc dryer, which is operating at pressure 6bar and a temperature of 160 °C.

Stick water contains dissolved protein, just like sugar dissolves in water. Proteins are valuable products and must be recovered to obtain a higher protein content and a better price. Waste heat evaporator use vapors from the disc dryer instead of steam from the boiler. The disc dryer evaporates water with a normal boiling point of 100 °C. The waste heat exchanger evaporates water using a vacuum where the boiling point is only 60 °C.

Falling film evaporator consists of:

- Vertical heat exchanger connected to disc dryer

- Circulation and vacuum pump

- Feed-in/out pumps

- Vertical or horizontal condenser

During the evaporator operation, the stick water will concentrate into a thick liquid, which is transferred to the dryer and combined with fish meal. Falling Film Evaporator is expensive equipment and requires a highly qualified employee to service. An evaporator can be installed after the installation of the whole fish meal line.

If you need more information about the available solutions, please contact us via the contact form on the last tab or by e-mail or call us.

For more technical information, please download our technical data sheet.

Approx. 50% saving on used fuel

Approx. 50% saving on used fuel

Download technical data sheet

Download technical data sheet